The manufacturing of solar panels involves the production of devices that are capable of converting sunlight into electricity. As the demand for renewable energy sources continues to increase, the solar panel manufacturing industry has experienced significant growth. This article aims to delve into the process of solar panel manufacturing, as well as the different technologies employed in the process.

The first step in solar panel manufacturing is the creation of silicon ingots. Silicon is the most commonly used material in solar panels, and it is sourced from quartz, abundant in the Earth’s crust. The silicon ingots are created through the Czochralski method, where a seed crystal is dipped into molten silicon and slowly pulled out to make a cylindrical ingot. The bar is then sliced into thin wafers using a saw.

Next, the wafers undergo a process called texturing, which involves etching the surface of the wafers to create tiny bumps and ridges. This increases the surface area of the wafers and allows them to absorb more sunlight. The textured wafers are then cleaned and coated with an anti-reflective layer to reduce the amount of the sun reflected away.

The next step is to create the solar cells themselves. This is done by doping the wafers with impurities such as boron and phosphorus, which make regions of positive and negative charge. When sunlight hits the solar cell, it excites electrons in the silicon, which then flow through the cell and generate an electrical current.

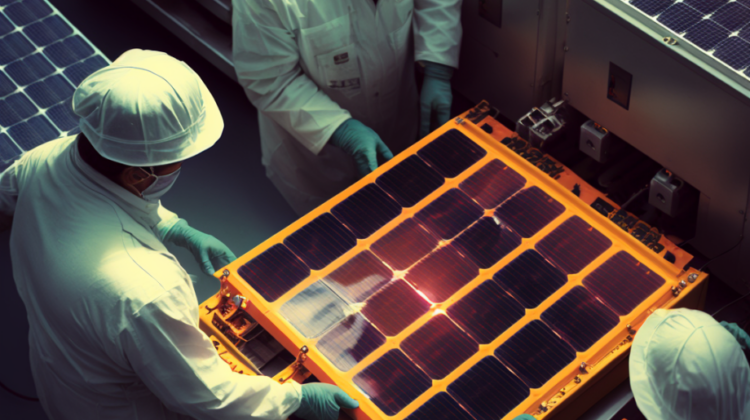

Once the solar cells have been created, they are assembled into solar panels. This involves soldering the cells and connecting them with wires to create a circuit. The solar cells are placed between two layers of protective material, such as glass or plastic, to create a durable panel that can withstand the elements.

There are multiple solar panel technologies to choose from, each with its own set of pros and cons. Among the various options, the crystalline silicon panel is the most widely used, produced using the process mentioned earlier. Although these panels are dependable and efficient, the cost of their manufacturing can be relatively high.

Another type of solar panel is the thin-film panel, which deposits a thin layer of semiconductor material onto a substrate such as glass or metal. Thin-film panels are cheaper to manufacture than crystalline silicon panels but are less efficient and have a shorter lifespan.

Finally, there are also emerging technologies, such as perovskite solar cells, made using a new type of semiconductor material called perovskite. Perovskite solar cells have the potential to be more efficient and cheaper to manufacture than traditional solar panels, but they are still in the early stages of development.

The process of manufacturing solar panels is intricate, involving a series of steps and technologies. It is a crucial component in promoting the use of renewable energy sources like solar power, which is gaining more significance in the fight against climate change. With technological advancements, solar panels are bound to become even more efficient and cost-effective, making them a desirable option for both homeowners and businesses.

Leave a Reply